Thermal Inspection System

Thermal Inspection System

ADTS has developed a comapact and lightweight Thermal Inspection System (TIS) capable of detecting the presence of humidity in the roof of tunnels.

Thermal Camera Enhanced Detection System

Overview

Our product leverages the advanced capabilities of the FLIR Ax5 thermal camera, known for its precise thermal imaging and ability to detect subtle temperature variations. The system excels in identifying structural issues, material inconsistencies, and environmental anomalies, providing enhanced analysis and inspection capabilities.

Key Features

Dual-Band Analysis

- Combines visible light imaging with thermal infrared (IR) imaging for comprehensive inspection.

- Detects features invisible in standard visible imaging, such as subsurface structures or temperature-related anomalies.

Precision and Versatility

- Operates at 30Hz with a maximum resolution of 640×480 for detailed thermal imaging.

- Ideal for use in both indoor and outdoor environments, even under challenging conditions like high humidity or varying solar exposure.

Use Cases

- Infrastructure Monitoring: Identifies water infiltration, structural damage, and material inconsistencies in concrete, plaster, and other construction materials.

- Thermal Gradient Analysis: Highlights temperature variations due to environmental factors or material properties.

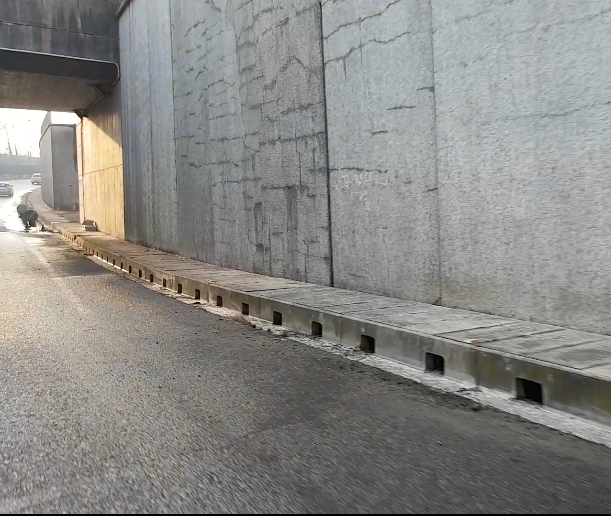

- Advanced Inspections: Effective in scenarios like tunnels or bridges, capturing details with both thermal and visible imaging.

Innovative Detection

- Pinpoints issues undetectable in IR, such as moisture without a thermal gradient, using complementary visible imaging.

- Visualizes temperature changes in real-time, enabling precise monitoring of thermal gradients.

Limitations

- Thermal Drift: Slight inaccuracies in absolute temperature readings over time, though relative measurements remain reliable.

- Calibration Interruptions: Brief pauses for sensor recalibration, ensuring long-term accuracy.

- Triggering Options: Operates in a continuous “free-run” mode; external trigger-based operation is not available.

Why Choose This System?

Our product harnesses the FLIR Ax5’s unique capabilities to provide unparalleled insights, optimizing detection and analysis for various applications. This robust integration of thermal and visible imaging ensures a thorough understanding of any scenario.

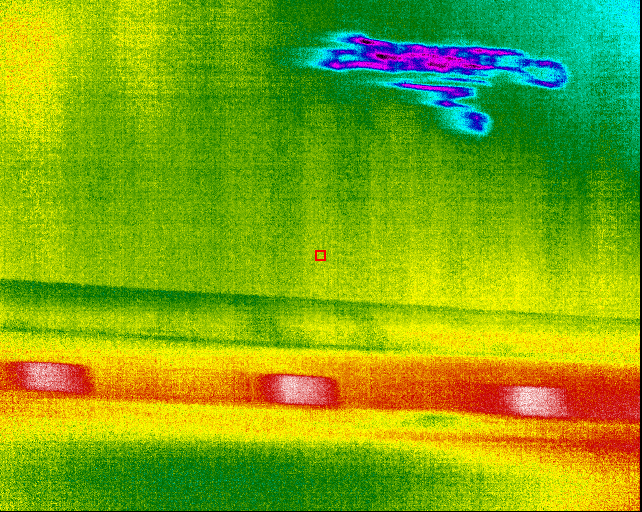

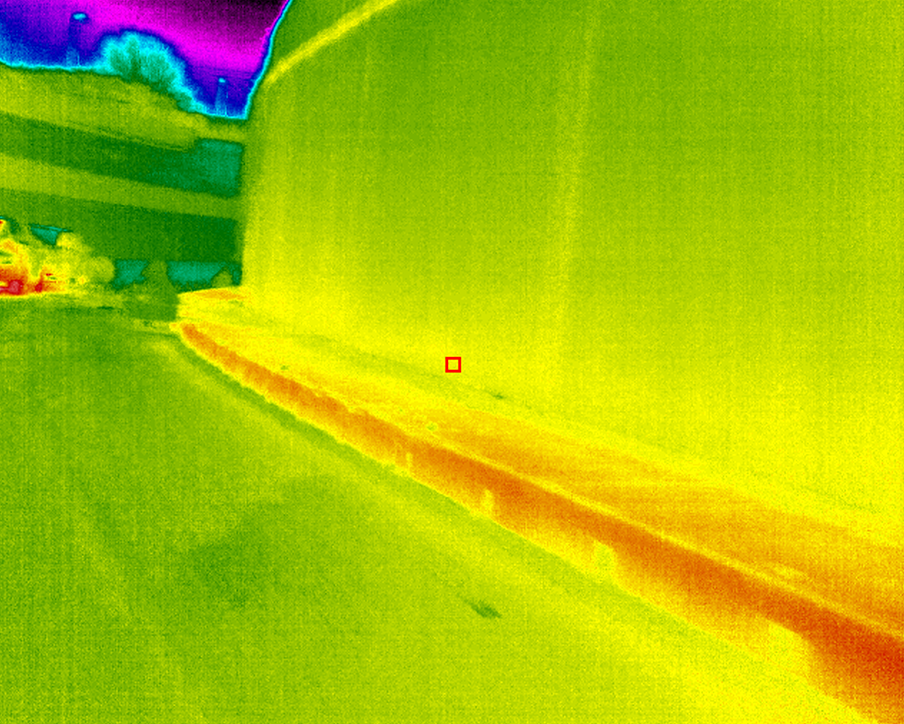

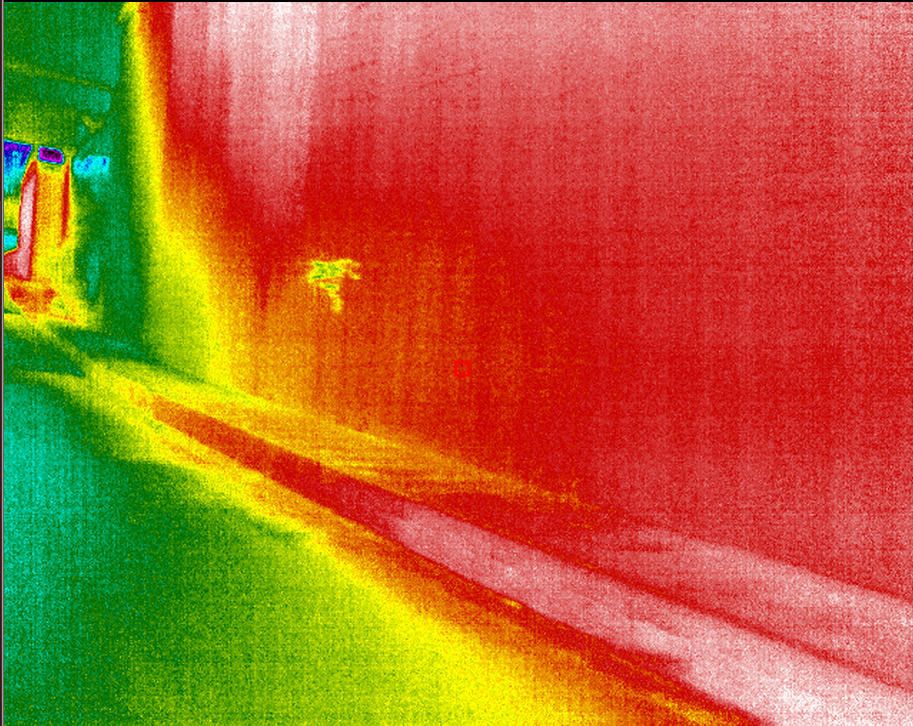

Revealing Hidden Anomalies with Thermal Imaging

The Machine View feature of our thermal imaging system refers to its ability to deliver a real-time, forward-facing perspective—similar to a driver’s or operator’s view—while simultaneously detecting subtle temperature variations in the surrounding environment. This advanced capability allows operators to uncover hidden or underlying issues in structures that are invisible to the naked eye or standard visible-light cameras, making it an essential tool in industrial inspections, infrastructure monitoring, and safety assessments.

How Machine View Works

In thermal imaging, different materials emit and retain heat differently. When moisture accumulates behind a wall or when a structural fault exists, those areas tend to show slight temperature differences compared to the surrounding material. These subtle thermal anomalies can go unnoticed with conventional tools but are clearly visible through our real-time thermal imaging technology.

The Machine View feature captures and displays these anomalies from a forward-facing perspective, giving operators a clear, continuous look ahead—perfect for inspections in dynamic environments such as tunnels, bridges, or industrial facilities. This capability is invaluable in applications like:

Detecting Moisture and Water Leaks: Water infiltration typically causes cooler zones. The system highlights these areas in real time, enabling early detection and preventive action.

Identifying Structural Issues: Irregular temperature patterns can signal problems such as insulation failure, voids, or cracks in materials. Machine View helps catch these issues early, before they become serious.

Assessing Energy Efficiency: By detecting areas where heat is escaping—through cracks, windows, or poorly insulated surfaces—the system provides actionable insights to improve building performance.

Thermal Palettes and Enhanced Visualization

To enhance anomaly detection, our system offers a range of thermal palettes. These color scales allow operators to highlight specific temperature ranges, making even the smallest irregularities easier to spot.

For example:

A water-damaged area behind a wall may appear cooler and stand out more in a palette using high contrast between blue and red.

A crack or weak spot may appear warmer in a palette tuned to highlight heat concentrations.

By adjusting the palette, operators can tailor the display to the context and conditions of the environment.

Real-Time Detection in Dynamic Environments

In scenarios where continuous monitoring is critical—such as transportation, structural inspections, or industrial operations—Machine View works seamlessly with real-time thermal imaging. With its front-facing orientation, it allows users to observe both the path ahead and surrounding structures for thermal anomalies as they appear.

This is especially valuable in enclosed environments like tunnels or pipelines, where hidden faults in walls or ceilings can pose safety risks. Machine View ensures that no critical details are missed, even in fast-moving or low-visibility conditions.