What is it?

Rail Corrugation is an irregularity that appears on the running surface of rails — tangentially, vertically, or axially.

It results from friction between the wheel and the lower rail during train operation.

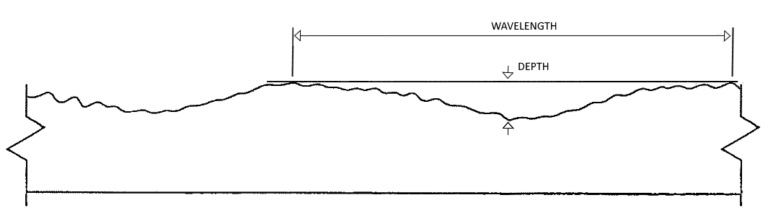

Excessive corrugation can be identified by the wavelength visible on the rail surface.

Corrugations are classified based on wavelength (the distance from peak to peak), while depth is defined as the distance between a peak and its adjacent valley.

The main wavelength bands are:

|

Very Short |

10 : 30 mm |

|

Short |

30 : 100 mm |

|

Medium |

100 : 300 mm |

|

Long |

300 : 1000 mm |

Types of corrugation

Rail corrugation takes different forms and has been categorized into six types:

- Heavy Haul

- Light Rail

- Sleeper-Induced

- Contact Fatigue

- Rutting

- Roaring Rails

These types are distinguished by their wavelength-fixing and damage mechanisms.

The most common wavelength-fixing mechanism is the P2 resonance of a vehicle’s unsprung mass on the track stiffness, which significantly contributes to half of these six types.

How corrugation can be limited?

So how can it be prevented?

Over time, various methods of prevention have been studied and developed for all six types of corrugation.

As mentioned, the excitation of a vehicle’s unsprung mass on the track stiffness remains the most common mechanism for wavelength fixation.

Corrugation measurement systems

The main method of detecting corrugation is through our Rail Corrugation Systems.

This is typically done using high-tech lasers paired with high-frequency cameras mounted on inspection platforms that travel along the rails, allowing a precise interpretation of the rail’s condition.

ADTS offers corrugation measurement systems for both trolley-based and vehicle-mounted applications.